Aiming for new horizons in manufacturing through “smart factories”

In the fourth industrial revolution (Industry 4.0), the integration of Internet of things (IoT), cloud computing and cognitive computing in manufacturing processes gave rise to smart factories and smart manufacturing. Smart factories comprise of fully connected and flexible systems that rely on data streaming from operation and production stream to learn and predict and consequently adjust and adapt to new demands and/or changing situations. The results are higher efficiency, increased production and decreased downtimes in manufacturing processes.

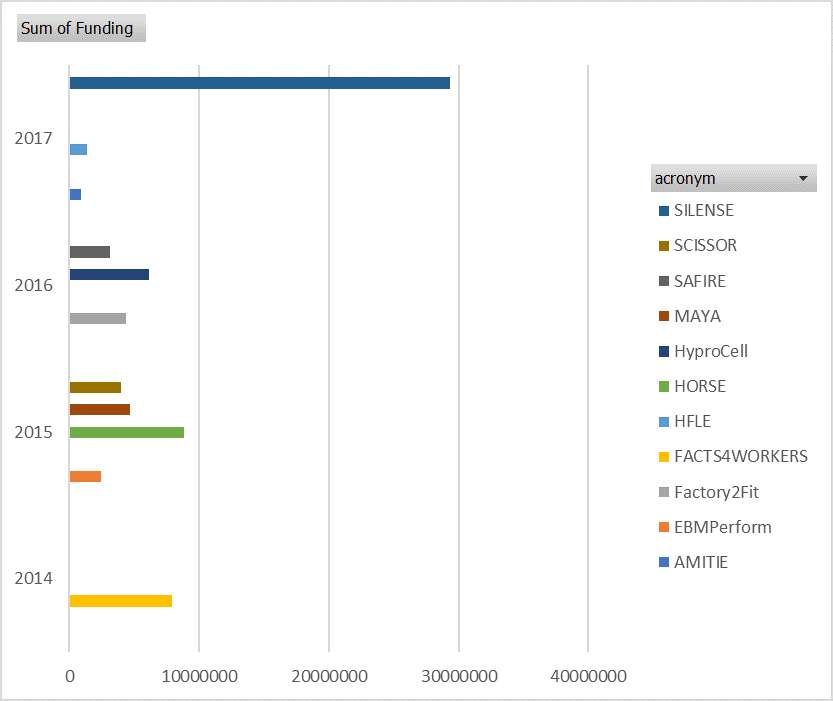

In the Horizon 2020 funding programme there is a relatively small number (12) of projects related to “smart factory”, “smart manufacturing”, “intelligent factory”, “smart production” and so on. The funding schemes supporting the twelve projects are distributed as follows: five projects were funded through the Innovation Action scheme (IA), five under the Research and Innovation Action (RIA) while one project each, was funded through Marie Curie Actions (MSCA) and SME schemes. Among the projects, the SILENSE project is the major effort within H2020 in the field of smart factories. With a budget of over 29 million euro, the SILENSE project has 30 participants in its consortium.

The most active Private entities within the “smart factories” projects are FINN-POWER OY (Finland), TTS Technology Transfer Systems Srl (Italy), and Continental Automotive GmbH (Germany). Other key organisations are TNO (Netherlands), TU Chemnitz (Germany), TU Eindhoven (Netherlands), IMEC (Belgium) and CEA (France).The insights on the various mature technological efforts from projects funded through the Innovation Action and Research and Innovation Action schemes are as follows:

The most active Private entities within the “smart factories” projects are FINN-POWER OY (Finland), TTS Technology Transfer Systems Srl (Italy), and Continental Automotive GmbH (Germany). Other key organisations are TNO (Netherlands), TU Chemnitz (Germany), TU Eindhoven (Netherlands), IMEC (Belgium) and CEA (France).The insights on the various mature technological efforts from projects funded through the Innovation Action and Research and Innovation Action schemes are as follows:

- Development of new generation Supervisory Control and Data Acquisition (SCADA) systems for detecting and thwarting threats targeting industrial installations. This system holistically combines multiple layers comprising of a monitoring layer for traffic probes, a control and coordination layer for gathering and consolidating heterogeneous data from different and remote probes, a decision and analysis layer and finally a human-machine layer that present system behavior to the human end user in a simplistic manner – SCISSOR project (RIA)

- Development and demonstration of workplace solutions that support the inclusion of increasing elements of knowledge work on the factory floor by empowering workers on the shop floor with smart factory ICT infrastructure – FACTS4WORKERS (IA)

- Technology fostering for SMEs by creating a methodological and technical framework to allow adaptation of robotic solutions and putting in place infrastructures and environments that will act as clustering points for selected application areas in manufacturing and for product lifecycle management – HORSE (IA).

- Provision of technology and infrastructure to enable Reconfiguration as a Service for dynamic smart factory systems and manufactured smart products that take advantage of cloud-based services and computing power to continually optimise the performance of manufacturing systems and products with respect to key performance characteristics including throughput, power consumption, utilization, maintenance and other factors – SAFIRE (RIA)

- Developing simulation methodologies and multidisciplinary tools for the design. engineering and management of CPS-based (Cyber-Physical Systems) Factories. These efforts are aimed at strategically supporting production-related activities during all the phases of the factory life-cycle, from the integrated design of the product-process- production system, through the optimization of the running factory, and finally through to the dismissal/reconfiguration phase – MAYA (RIA)

- Supporting the development of increased automation and increased customization in smart factories by encouraging flexible and adaptive work organization is crucial both for productivity and work satisfaction. This will be achieved by developing adaptation solutions with which people with different skills. capabilities and preferences can be engaged. motivated and productive members of the work community in manufacturing industries – Factory2Fit (RIA)

- With smart homes and smart factories in mind, develop smart acoustic technologies and ultrasound intended for Human to Machine and Machine to Machine Interfaces by applying acoustics a touchless activation and control mechanism and developing different smart acoustic technology blocks (hardware, software and system level) and integrating these blocks at system level – SILENSE (RIA)

- Laser-based Additive Manufacturing (LBAM) lacks competitiveness in terms of (i) lack of integration with production planning systems which hinders process traceability and resource optimisation and (ii) the need for human intervention, especially in post-processing operations. Thus, a multiprocess production cell will be developed which integrates cutting-edge LBAM machines and ICT innovations produce a fully finished product from the incoming raw material – HyproCell (IA)

- Demonstrate a set of integrated tools for the rapid and autonomous reconfiguration of agile production systems, both at operational as well as managerial levels, integrated with the existing production planning and scheduling tools. These next-generation flexible production systems and the proposed set of enabling ICT tools will allow a rapid and cost-efficient reaction to dynamic market changes, also in small-lot production contexts, reducing the efforts needed to switch between product types and production quantities – ReCaM (IA)

The relevant open and forthcoming calls on smart factories are as follows:

DT-ICT-01-2019: Smart Anything Everywhere

DT-ICT-02-2018: Robotics – Digital Innovation Hubs (DIH)

DT-ICT-06-2018: Coordination and Support Activities for Digital Innovation Hub network

DT-ICT-07-2018-2019: Digital Manufacturing Platforms for Connected Smart Factories

DT-ICT-10-2018-19: Interoperable and smart homes and grids

DT-ICT-11-2019: Big data solutions for energy

DT-ICT-13-2019: Digital Platforms/Pilots Horizontal Activities

DT-ICT-01-2019: Smart Anything Everywhere

DT-ICT-02-2018: Robotics – Digital Innovation Hubs (DIH)

DT-ICT-06-2018: Coordination and Support Activities for Digital Innovation Hub network

DT-ICT-07-2018-2019: Digital Manufacturing Platforms for Connected Smart Factories

DT-ICT-10-2018-19: Interoperable and smart homes and grids

DT-ICT-11-2019: Big data solutions for energy

DT-ICT-13-2019: Digital Platforms/Pilots Horizontal Activities